Knowledge

Is Tab Washer the Best Bolt Locking Method?

Tab washers or Nord-Lock washers? Finding the ultimate bolt securing system is no easy task. Here is a guide to making the right choice.

| Tab Washers | Nord-Lock Wedge-Locking | |

| Locking capability | Relatively good | Reliable |

| Range | Normally not available for large sizes. | M3-M130 (standard range) |

| Temperature | Same temperature characteristics as regular bolts/nuts. | Same temperature characteristics as regular bolts/nuts. |

| Assembly/disassembly routines | Complex and time-consuming assembly/disassembly. Requires enough space, additional tools and a skilled operator. | Simple and rapid assembly/disassembly. No special tools or preparation required. |

| Control of clamp load | Friction conditions must first be verified in order to predict the clamp load. | Linear relationship between torque/load – thus possible to predict the clamp load. |

| Risk of damage to assembled parts | Some risk. Requires deformation of the washer through shocks, which can damage the assembled parts. | No risk. Fine impression marks on bolt head/nut, as well as underlying surfaces. |

| Reusability | Not reusable | Reusable |

| Environment and safety | Recyclable. Manual assembly routines and long assembly time increase risk of injury, human error and damage to parts. |

Recyclable. Minimal risk of human injury or error. Rapid assembly time results in minimal exposure in dangerous areas. |

| Lubrication | Possible to lubricate. | Possible to lubricate. |

| Use in confined spaces | Limited use in confined spaces, due to complex assembly requirements. | Suitable for use and easy to assemble in confined spaces. |

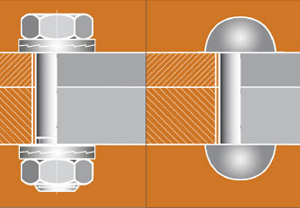

| Use with through holes | Time-consuming and difficult to use with through holes. Note that washers on both sides of the assembled parts are required. | Suitable. Note that washers on both sides of the assembled parts are required. |

| Use with hex cap screw (ISO 4762) | Not possible | Possible |

| Counterbores | Not possible | Possible |

| Life cycle cost (LCC) | High. Short life cycle. A large number of units must be purchased as washers are neither reusable nor standardized. | Low. Relatively high price per unit. Long life cycle. Standardized and reusable items improve stability and minimize maintenance costs. |

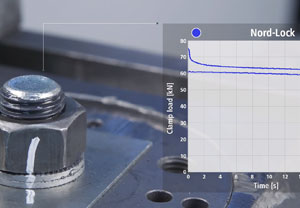

Junker vibration test comparison of tab washers vs wedge-locking washers